Spinning & Twisting

With about 50,000 spindles of spinning units, we are capable to produce 1000 MT of spun polyester yarn of different counts, from 20s to 50s, per month .

To ensure the production with top quality yarn, our spinning unit is equipped with Japanese origin TOYOTA, MURATA AUTO CONER, Switzerland origin RIETER, spinning machines and DRAW FRAME FINISHER.

Yarn Dyeing

With about 50,000 spindles of spinning units, we are capable of producing about 1000 MT of spun polyester yarn of different counts, from 20s to 50s, per month .

To ensure the production with top quality yarn, our spinning unit is equipped with Japanese origin TOYOTA, MURATA AUTO CONER, Switzerland origin RIETER, spinning machines and DRAW FRAME FINISHER.

Sampling Unit

Our sampling unit is equipped with all the modern machineries of a high-tech laboratory for checking the quality of the developed samples.

Specialties

Swatch Analysis (A. Examining Buyer’s swatch- Fabric swatch or hard copy. B. After ensuring fabric construction- Start for Back process.)

Sizing

Warping (The threads are rolled in the roll) Drawer (The design/pattern setter).

Weaving (By two sets of Desk looms, we are making sty-cuff and mini PP Yardage for all kinds of Yarn dyed fabrics)

Swatch room (for examining GSM)

Customer Satisfaction:

We deliver all required sty-cuff’s to our buyers within 24 to 48 hours only because we measure our best business strategy by our satisfied customers. We view Quality, Price & Service as one entity. Our purpose is to produce high

quality product at competitive price and provide international standard customer service to, maintain the leading position.

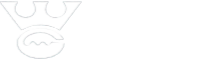

Winding

Winding is the process of transferring yarn or thread from one type of package to another to facilitate subsequent processing. The re-handling of yarn is an integral part of the fiber and textile industries.

Not only must the package and the yarn itself be suitable for processing on the next machine in the production process, but also other factors such as packing cases, pressure due to winding tension, etc. must be considered.

In WELL FABRIC’s, there are two types of winding machine : one precision winder and three drum winders. Precision winders, used primarily for filament yarn, have traverse driven by a cam that is synchronized with the spindle and produce packages with a diamond pattered wind. Drum winders are used principally for spun yarns; the package is driven by frictional contact between the surface of the package and the drum.

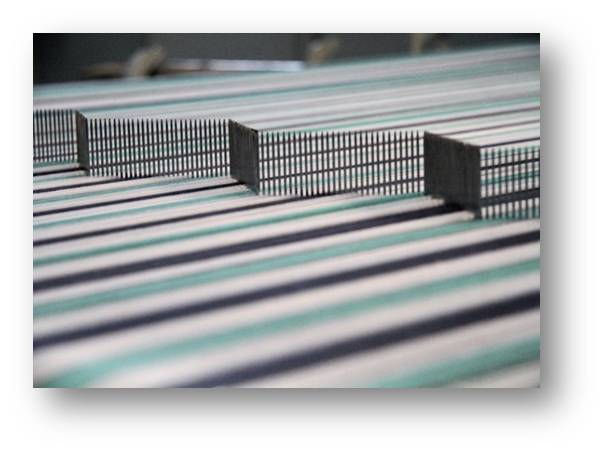

Warping

In sectional warping, the construction is done section by section.

At Well Fabrics, sectional warper’s offer the latest technology in an ergonomic design, and they achieve highest quality for optimum result in weaving.

Warping process is the basis of woven and it has direct impact on quality of final product.

Our highly compliant factory has the required reliability and designed to achieve prime quality warping in all kinds of production.

Built in steel bedframes joined by crossbeams of the machines ensures a rigid and robust construction, allowing vibrant-free high speed operation during production.

The continuous movement of the warping unit ensures constant angles at the drum yarn inlet. In order to have export quality output, all the raw materials are imported from China to avoid minimum product variation.

Sizing

Sizing of the warp yarn is essential to reduce breakage of the yarn. With sizing, the strength abrasion resistance of the yarn will improve and the hairiness of yarn will decrease in order to ensure the best performance.

Our Sizing unit considers all parameters like pickup, stretch, moisture, and other appropriate characteristics that guarantee high quality warp beams and sized beams.

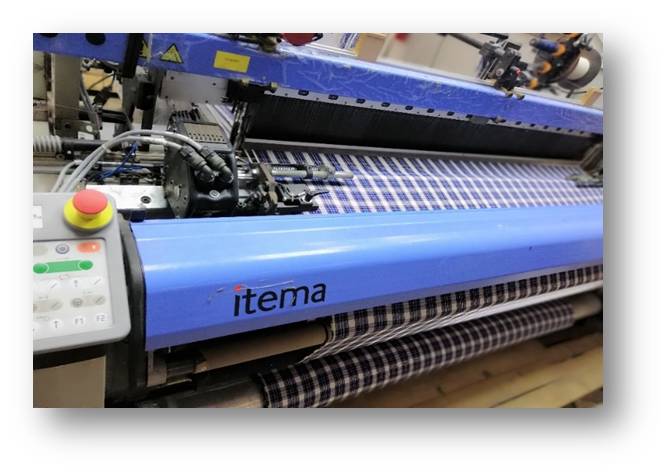

Weaving

WELL FABRIC’s weaving unit focuses on the fabric quality from every edge of manufacturing process.

We weave all types of woven fabrics like denim, chambray, yarn dyed chambray, yarn blended CVC satin, 100% cotton satin, check, poplin, twill fabrics backed up by highly professional production team.