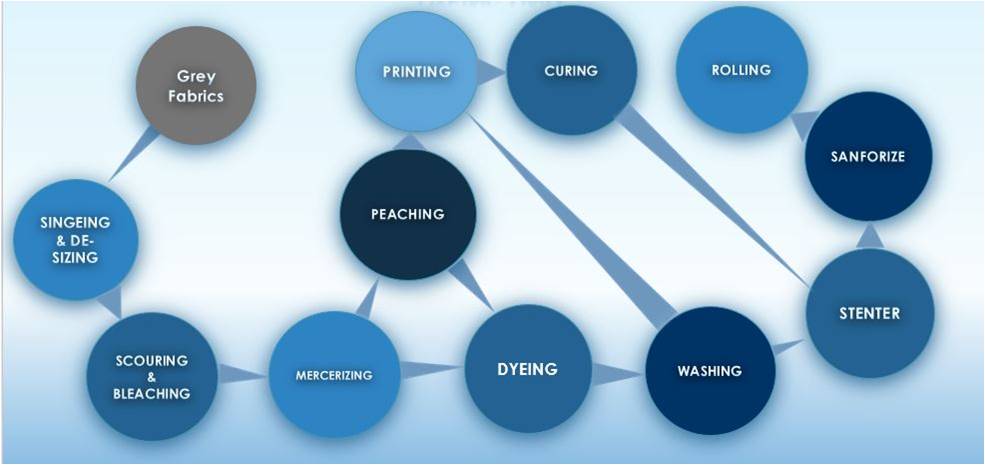

Process Flow of DYEING UNIT

Gas Singeing & De-sizing Machine

Scouring & Bleaching Machine

Mercerizing Machine

Washing Machine

Peach Machine

Cold Pad Batch

Sanforizing Machine

Jigger Dyeing Machine

Chambered Stenter Machine with MAHLO

Inspection Machine

Laboratory

Mending

Newly made goods, which frequently show imperfections, are carefully inspected, and defects are usually repaired by hand operations.

The first inspection of woolen and worsted, spun rayon, and cotton fabrics, is the process of removing any remaining foreign matter, such as burrs and also any loose threads, knots, and undesired slub’s.

Mending, frequently necessary for woolens and worsteds, eliminates such defects as holes or tears, broken yarns, and missed warp or weft yarns.

Inspection

Fabric inspection is done for fault/defect rate, fabric construction, end to end or edge to edge shading, color, hand or feel, length/width, print defect and appearance.

Some garment manufacturers rely on their fabric suppliers to perform fabric inspection and fabric defects.

That is why, Well Fabrics has made an arrangement to bring perfection in all kinds of Fabrics inspection.